Automation System Engineer

Basics of Relays, Contactor, MCB, MCCB, ELCB, RCD, ACB

Relays:

A relay is an electrically operated switch. Many relays use an electromagnet to operate a switching mechanism mechanically, but other operating principles are also used. Relays are used where it is necessary to control a circuit by a low-power signal (with complete electrical isolation between control and controlled circuits), or where several circuits must be controlled by one signal.

For better Understanding click the following links:

Relay-1, Relay-2

For better Understanding click the following links:

RCD:

Working details of different types of Electric Motors:

The motor or an electrical motor is a device that has brought about one of the biggest advancements in the fields of engineering and technology ever since the invention of electricity. A motor is nothing but an electro-mechanical device that converts electrical energy to mechanical energy. Its because of motors, life is what it is today in the 21st century. Without motor we had still been living in Sir Thomas Edison’s Era where the only purpose of electricity would have been to glow bulbs. There are different types of motor have been developed for different specific purposes. In simple words we can say a device that produces rotational force is a motor. The very basic principal of functioning of an electrical motor lies on the fact that force is experienced in the direction perpendicular to magnetic field and the current, when field and electric current are made to interact with each other. Ever since the invention of motors, a lot of advancements has taken place in this field of engineering and it has become a subject of extreme importance for modern engineers. This particular webpage takes into consideration, the above mentioned fact and provides a detailed description on all major electrical motors and motoring parts being used in the present era. Motor Starting and Running Currents and Rating Guide: A word of caution: The following article is based on National Electrical Manufacturers' Association (NEMA) tables, standards and nomenclature. This is somewhat different from Indian and European practice. The class designations are applicable only to NEMA compatible motors which are in use in the US only. However, the logic and pattern of calculations are the same everywhere. Hence the reader is cautioned to follow only the logical sequence of the calculations. Motor Starting Current: When typical induction motors become energized, a much larger amount of current than normal operating current rushes into the motor to set up the magnetic field surrounding the motor and to overcome the lack of angular momentum of the motor and its load. As the motor increases to slip speed, the current drawn subsides to match (1) the current required at the supplied voltage to supply the load and (2) losses to windage and friction in the motor and in the load and transmission system. A motor operating at slip speed and supplying nameplate horsepower as the load should draw the current printed on the nameplate, and that current should satisfy the equation

Electrical Motor,

Working of ElectricMotor,

DC Motor,

Working Principle of DCMotor

Construction of DCMotor

Torque Equation of DC Motor

Types of DC Motor

Shunt Wound DC Motor

Series Wound DC Motor

Compound Wound DC Motor

Starting Methods of DCMotor

Three Point Starter

Four Point Starter

Speed Regulation of DC Motor

Speed Control of DCMotor

Three Phase InductionMotor

Linear Induction Motor

Synchronous Motor

Synchronous MotorExcitation

Hunting in SynchronousMotor

Motor Generator Set

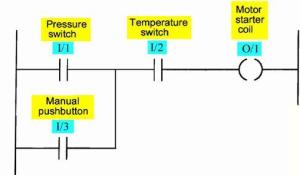

Designing of control circuits using Contactors, Relays, Timers etc:

DOL, Star Delta Starter designing for 3 phase motors with specification:

DOL Starter:

Different starting methods are employed for starting induction motors because Induction Motor draws more starting current during starting. To prevent damage to the windings due to the high starting current flow, we employ different types of starters.

Contactors & Coil:

DOL part -Contactor:

Direct On Line Starter - Wiring Diagram

DOL - Wiring scheme

STAR DELTA connection Diagram and Working principle:

Whenever the term electric motor or generator is used, we tend to think that the speed of rotation of these machines is totally controlled only by the applied voltage and frequency of the source current. But the speed of rotation of an electrical machine can be controlled precisely also by implementing the concept of drive. The main advantage of this concept is, the motion control is easily optimized with the help of drive. In very simple words, the systems which control the motion of the electrical machines, are known as electrical drives. A typical drive system is assembled with a electric motor (may be several) and a sophisticated control system that controls the rotation of the motor shaft. Now a days, this control can be be done easily with the help of software. So, the controlling becomes more and more accurate and this concept of drive also provides the ease of use. This drive system is widely used in large number of industrial and domestic applications like factories, transportation systems, textile mills, fans, pumps, motors, robots etc. Drives are employed as prime movers for diesel or petrol engines, gas or steam turbines, hydraulic motors and electric motors. Now coming to the history of electrical drives, this was first designed in Russia in the year 1838 by B.S.Iakobi, when he tested a DC electric motor supplied from a storage battery and propelled a boat. Even though the industrial adaptation occurred after many years as around 1870. Today almost everywhere the application of electric drives is seen. The very basic block diagram an electric drives is shown below. The load in the figure represents various types of equipments which consists of electric motor, like fans, pumps, washing machines etc.

Classification of electrical drives:

i. AC to DC converters

ii. ac Regulators

iii. Choppers or dc-dc converters

iv. Inverters

v. Cycloconverters AC to DC converters are used to obtain fixed dc supply from the ac supply of fixed voltage.

The very basic diagram of ac to dc converters is like.

Inverters are used to get ac from dc, the operation is just opposite to that of ac to dc converters. PWM semiconductors are used to invert the current.

Cyclo-converters are used to convert the fixed frequency and fixed voltage ac into variable frequency and variable voltage ac. Thyristors are used in these converters to control the firing signals.

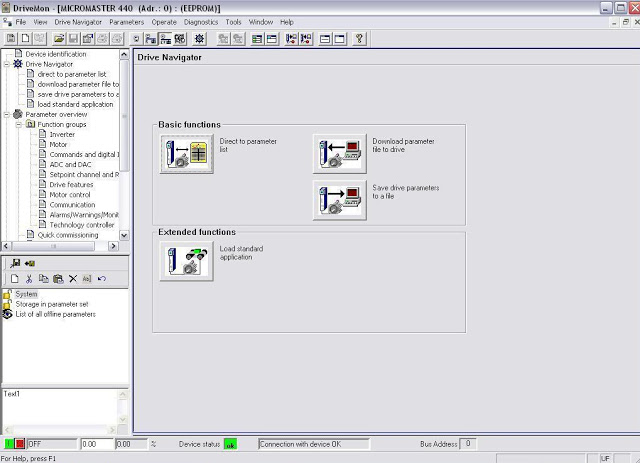

3. Open DriveMon Software & go to FileàSet up an USS ONLINE connection as shown below:

4. In window click on Start (After this software will detect online drive automatically and will go online:

5. Check Device Status.

6. For taking parameter back up click on:

7. Select option “Basic Device complete”:

8. Save parameter file to required location:

9. Wait till upload finishes.:

11. For restoring parameter back up Click on

Discrete and Continuous speed control using VFDs:

Select the proper size for the load. When specifying VFD size and power ratings, consider the operating profile of the load it will drive. Will the loading be constant or variable? Will there be frequent starts and stops, or will operation be continuous? Consider both torque and peak current. Obtain the highest peak current under the worst operating conditions. Check the motor FLA, which is located on the motor's nameplate. Note that if a motor has been rewound, its FLA may be higher than what's indicated on the nameplate. Don't size the VFD according to horsepower ratings. Instead, size the VFD to the motor at its maximum current requirements at peak torque demand. The VFD must satisfy the maximum demands placed on the motor. Consider the possibility that VFD oversizing may be necessary. Some applications experience temporary overload conditions because of impact loading or starting requirements. Motor performance is based on the amount of current the VFD can produce. For example, a fully-loaded conveyor may require extra breakaway torque, and consequently increased power from the VFD. Many VFDs are designed to operate at 150% overload for 60 seconds. An application that requires an overload greater than 150%, or for longer than 60 seconds, requires an oversized VFD. Altitude also influences VFD sizing, because VFDs are air-cooled. Air thins at high altitudes, which decreases its cooling properties. Most VFDs are designed to operate at 100% capacity up to an altitude of 1,000 meters; beyond that, the drive must be derated or oversized. Be aware of braking requirements.

Duration: - 240 Hours Content of the Training: The training program is broadly divided into six sessions. Each session is taken by experts with industry experience. As the world of automation is intensifying as each day progresses, engineers can't survive without proper training from the ground level to the advanced level. Our course is highly practical-oriented, aimed at supporting and encouraging fresh engineers to foray into the automation industry and fine tune each engineer personnel.

Six major sessions in which training imparted are:

•Electrical drives and controls.

•Field Instrumentation

•Programmable Logic Controllers (PLC) - Allen-Bradley, Siemens, ABB, Telemecanique PLCs

•Supervisory Control and Data Acquisition (SCADA).

•Introduction to Distributed Control System (DCS) •Control panel designing. 1. Electrical drives and controls

•Basics of Relays, Contactor, MCB, MCCB, ELCB, ACB,SDF etc •Working details of different types of Electric Motors.

•Designing of control circuits using Contactors, Relays, Timers etc •DOL, Star Delta Starter designing for 3 phase motors with specification. •Practical wiring session on different controls.

•Motor drives- AC drives and DC drives.

•Programming and installation of VFDs.

•Discrete and Continuous speed control using VFDs.

•Safety and management concepts of designing a project.

2. Field Instrumentation

•Different types of sensors- analog and discrete

•Technical terms used in instrumentation

•Calibration and testing of sensors- thermo couples, RTD, pressure gauge, level sensors, proximity switches, limit switches etc

•Final control elements- Solenoid valve, control valve, motor actuators, Solenoids, bellows, manual valves etc

•Wiring and commissioning of reactor plant with PLC and SCADA control

3. Programmable Logic Controllers (PLC)

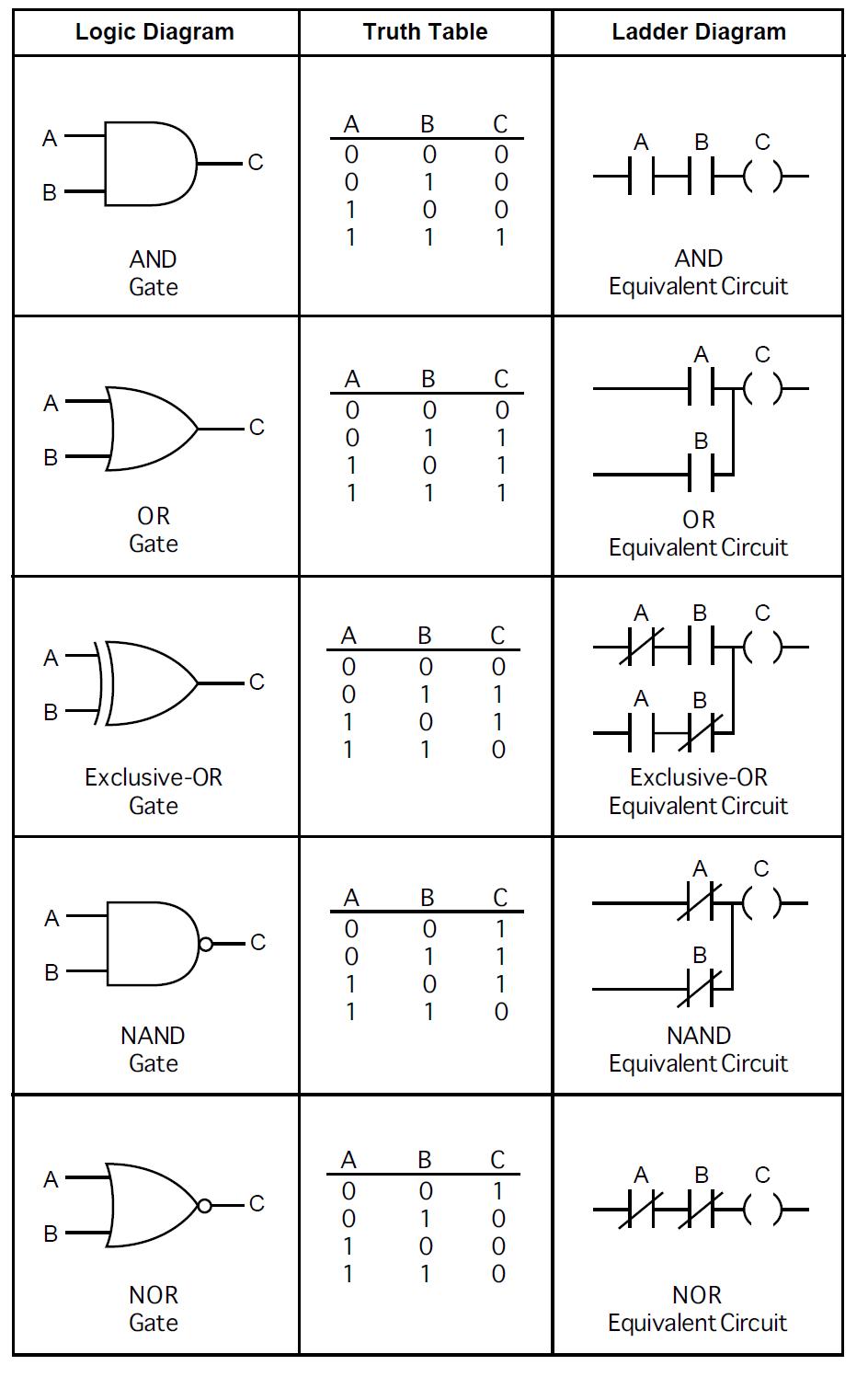

•Architecture of PLC- different modules, power supply unit etc •Need of PLC in designing.

•Different types of sensors- sinking, sourcing, NPN, PNP. •Monitoring the process through sensors- connection details.

•Analog addressing continues process monitoring and control.

•Different types of controllers- ON/OFF, Proportional, Derivative, Integral and PID control.

•PLC Programming of branded PLCs.

•NO/ NC concept. •Data file handling- forcing I/O.

•Wiring and fault correction.

•Programming practices.

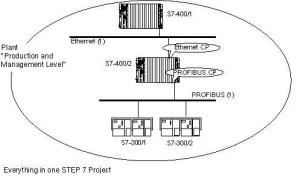

4. Supervisory Control And Data Acquisition (SCADA).

•SCADA Packages

•Role of SCADA in industrial automation

•SCADA system configuration, RTU, communication protocols.

•Script programming.

•Real time and historical trend.

•Configuring Alarms.

•Real time project development with PLC interfacing.

•Communication with other software.

•Recipe management.

•Accessing different security levels.

•Report generation of current plant.

5 . Introduction to DCS

•Architecture of DCS

•Yokogawa Centum CS 3000

•Comparison of PLC with DCS

•Programming languages for DCS

•Different types of cards and their functions

6 . Control Panel Designing

•Different types of panels.

•Basic components to be installed in a panel.

•Wiring details of panel.

•Specification and physical dimension of components.

•Earthing and Cabling of Panels- standard procedures.

•P&I diagram

1. Electrical drives and controls

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

Basics of Relays, Contactor, MCB, MCCB, ELCB, RCD, ACB

Relays:

A relay is an electrically operated switch. Many relays use an electromagnet to operate a switching mechanism mechanically, but other operating principles are also used. Relays are used where it is necessary to control a circuit by a low-power signal (with complete electrical isolation between control and controlled circuits), or where several circuits must be controlled by one signal.

For better Understanding click the following links:

Relay-1, Relay-2

A contactor is an electrically controlled switch used for switching a power circuit, similar to a relay except with higher current ratings.A contactor is controlled by a circuit which has a much lower power level than the switched circuit.

For better Understanding click the following links:

Link-1, Link-2

MCB:

For better Understanding click the following links:

Link-1, Link-2

MCB:

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overload or short circuit. Its basic function is to detect a fault condition and interrupt current flow. Unlike a fuse, which operates once and then must be replaced, a circuit breaker can be reset (either manually or automatically) to resume normal operation. Circuit breakers are made in varying sizes, from small devices that protect an individual household appliance up to large switch-gear designed to protect high-voltage circuits feeding an entire city

For better Understanding click the following links: Link-1, Link-2, Link-3

For better Understanding click the following links: Link-1, Link-2, Link-3

MCCB:

Molded case circuit breakers provide circuit over-current protection with inverse time and instantaneous tripping characteristics. MCCB’s have a quick-make, quick-break over center toggle type mechanism and the handle mechanism shall be trip free to prevent holding contacts closed against a short circuit or sustained overload. MCCB handles assume a position between “ON” and “OFF” when tripped automatically. Multi-pole circuit breakers have common-trip such that an overload or short circuit on any one pole will result in all poles opening simultaneously. Shunt trips, bell alarms, and auxiliary switches are provided. Gold plated auxiliary switches shall be supplied for PLC connection. Internal accessories for all breakers shall be UL listed for field installation and modification.

Molded case circuit breakers provide circuit over-current protection with inverse time and instantaneous tripping characteristics. MCCB’s have a quick-make, quick-break over center toggle type mechanism and the handle mechanism shall be trip free to prevent holding contacts closed against a short circuit or sustained overload. MCCB handles assume a position between “ON” and “OFF” when tripped automatically. Multi-pole circuit breakers have common-trip such that an overload or short circuit on any one pole will result in all poles opening simultaneously. Shunt trips, bell alarms, and auxiliary switches are provided. Gold plated auxiliary switches shall be supplied for PLC connection. Internal accessories for all breakers shall be UL listed for field installation and modification.

Circuit breakers 2000 Ampere and below shall have thermal-magnetic trip units, with inverse time-current characteristics. Automatic operation of these circuit breakers shall be obtained by means of thermal magnetic tripping devices located in each pole providing inverse time delay and instantaneous circuit protection. Circuit breakers shall be ambient compensating in that, as the ambient temperature increases over 40ºC, the circuit breaker automatically de-rates itself so as to better protect its associated conductor.

Thermal-magnetic breakers from 250 to 2000A frames shall have thermal interchangeable trip units, with instantaneous magnetic trip settings that are adjustable and accessible from the front of all circuit breakers on frame sizes 250 Amperes and above. Where indicated, provide circuit breakers UL listed for application at 100% of their continuous ampere rating in their intended enclosure.

For better Understanding click the following links:

ELCB: An earth leakage circuit breaker (ELCB) is a device with two earth terminals used to directly detect currents leaking to earth from an installation and cut the power. They were mainly used on TT earthing systems. By having the assumption of the presence of current in the earth line, it means there is any leaking current from the main incoming live cable, thus the power has to be cut off to ensure the safety. State of ELCB when it cuts the power is called tripped. Every time the ELCB tripped, we can reset it back (Connect back the power line) by resetting the trip button.

RCD:

A residual-current device (RCD), or residual-current circuit breaker (RCCB), is an electrical wiring device that disconnects a circuit whenever it detects that the electric current is not balanced between the energized conductor and the return neutral conductor. Such an imbalance may indicate current leakage through the body of a person who is grounded and accidentally touching the energized part of the circuit. A lethal shock can result from these conditions. RCCBs are designed to disconnect quickly enough to prevent injury caused by such shocks. They are not intended to provide protection against over current (overload) or short-circuit conditions.

For better Understanding click the following links: Link-1

ACB:

For better Understanding click the following links: Link-1

ACB:

This type of circuit breakers, is those kind of circuit breaker which operates in air at atmospheric pressure. After development of oil breaker, the medium voltage air circuit breaker (ACB) is replaced completely by oil circuit breakerin different countries. But in countries like France and Italy, ACBs are still preferable choice up to voltage 15 KV. It is also good choice to avoid the risk of oil fire, in case of oil circuit breaker. In America ACBs were exclusively used for the system up to 15 KV until the development of new vacuum and SF6 circuit breakers.

Working principle of Air Circuit Breaker: The working principle of this breaker is rather different from those in any other types of circuit breakers. The main aim of all kind of circuit breaker is to prevent the reestablishment of arcing after current zero by creating a situation where in the contact gap will withstand the system recovery voltage. The air circuit breaker does the same but in different manner. For interrupting arc it creates an arc voltage in excess of the supply voltage. Arc voltage is defined as the minimum voltage required maintaining the arc. This circuit breaker increases the arc voltage by mainly three different ways,It may increase the arc voltage by cooling the arc plasma. As the temperature of arc plasma is decreased, the mobility of the particle in arc plasma is reduced; hence more voltage gradient is required to maintain the arc. It may increase the arc voltage by lengthening the arc path. As the length of arc path is increased, the resistance of the path is increased, and hence to maintain the same arc current more voltage is required to be applied across the arc path. That means arc voltage is increased. Splitting up the arc into a number of series arcs also increases the arc voltage. Types of ACB: There are mainly two types of ACB are available. 1) Plain air circuit breaker 2) Air blast Circuit Breaker. Operation of ACB: The first objective is usually achieved by forcing the arc into contact with as large an area as possible of insulating material. Every air circuit breaker is fitted with a chamber surrounding the contact. This chamber is called ‘arc chute’. The arc is driven into it. If inside of the arc chute is suitably shaped, and if the arc can be made conform to the shape, the arc chute wall will help to achieve cooling. This type of arc chute should be made from some kind of refractory material. High temperature plastics reinforced with glass fiber and ceramics are preferable materials for making arc chute. The second objective that is lengthening the arc path, is achieved concurrently with fist objective. If the inner walls of the arc chute is shaped in such a way that the arc is not only forced into close proximity with it but also driven into a serpentine channel projected on the arc chute wall. The lengthening of the arc path increases the arc resistance. The third technique is achieved by using metal arc slitter inside the arc chute. The main arc chute is divided into numbers of small compartments by using metallic separation plates. These metallic separation plates are actually the arc splitters and each of the small compartments behaves as individual mini arc chute. In this system the initial arc is split into a number of series arcs, each of which will have its won mini arc chute. So each of the split arcs has its won cooling and lengthening effect due to its won mini arc chute and hence individual split arc voltage becomes high. These collectively, make the over all arc voltage, much higher than the system voltage. This was working principle of air circuit breaker now we will discuss in details the operation of ACB in practice. The air circuit breaker, operated within the voltage level 1KV, does not require any arc control device. Mainly for heavy fault current on low voltages (low voltage level above 1 KV) ABCs with appropriate arc control device, are good choice. These breakers normally have two pairs of contacts. The main pair of contacts carries the current at normal load and these contacts are made of copper. The additional pair is the arcing contact and is made of carbon. When circuit breaker is being opened, the main contacts open first and during opening of main contacts the arcing contacts are still in touch with each other. As the current gets, a parallel low resistive path through the arcing contact during opening of main contacts, there will not be any arcing in the main contact. The arcing is only initiated when finally the arcing contacts are separated. The each of the arc contacts is fitted with an arc runner which helps, the arc discharge to move upward due to both thermal and electromagnetic effects as shown in the figure. As the arc is driven upward it enters in the arc chute, consisting of splitters. The arc in chute will become colder, lengthen and split hence arc voltage becomes much larger than system voltage at the time of operation of air circuit breaker, and therefore the arc is quenched finally during the current zero. Although this type of circuit breakers have become obsolete for medium voltage application, but they are still preferable choice for high current rating in low voltage application.

Working principle of Air Circuit Breaker: The working principle of this breaker is rather different from those in any other types of circuit breakers. The main aim of all kind of circuit breaker is to prevent the reestablishment of arcing after current zero by creating a situation where in the contact gap will withstand the system recovery voltage. The air circuit breaker does the same but in different manner. For interrupting arc it creates an arc voltage in excess of the supply voltage. Arc voltage is defined as the minimum voltage required maintaining the arc. This circuit breaker increases the arc voltage by mainly three different ways,It may increase the arc voltage by cooling the arc plasma. As the temperature of arc plasma is decreased, the mobility of the particle in arc plasma is reduced; hence more voltage gradient is required to maintain the arc. It may increase the arc voltage by lengthening the arc path. As the length of arc path is increased, the resistance of the path is increased, and hence to maintain the same arc current more voltage is required to be applied across the arc path. That means arc voltage is increased. Splitting up the arc into a number of series arcs also increases the arc voltage. Types of ACB: There are mainly two types of ACB are available. 1) Plain air circuit breaker 2) Air blast Circuit Breaker. Operation of ACB: The first objective is usually achieved by forcing the arc into contact with as large an area as possible of insulating material. Every air circuit breaker is fitted with a chamber surrounding the contact. This chamber is called ‘arc chute’. The arc is driven into it. If inside of the arc chute is suitably shaped, and if the arc can be made conform to the shape, the arc chute wall will help to achieve cooling. This type of arc chute should be made from some kind of refractory material. High temperature plastics reinforced with glass fiber and ceramics are preferable materials for making arc chute. The second objective that is lengthening the arc path, is achieved concurrently with fist objective. If the inner walls of the arc chute is shaped in such a way that the arc is not only forced into close proximity with it but also driven into a serpentine channel projected on the arc chute wall. The lengthening of the arc path increases the arc resistance. The third technique is achieved by using metal arc slitter inside the arc chute. The main arc chute is divided into numbers of small compartments by using metallic separation plates. These metallic separation plates are actually the arc splitters and each of the small compartments behaves as individual mini arc chute. In this system the initial arc is split into a number of series arcs, each of which will have its won mini arc chute. So each of the split arcs has its won cooling and lengthening effect due to its won mini arc chute and hence individual split arc voltage becomes high. These collectively, make the over all arc voltage, much higher than the system voltage. This was working principle of air circuit breaker now we will discuss in details the operation of ACB in practice. The air circuit breaker, operated within the voltage level 1KV, does not require any arc control device. Mainly for heavy fault current on low voltages (low voltage level above 1 KV) ABCs with appropriate arc control device, are good choice. These breakers normally have two pairs of contacts. The main pair of contacts carries the current at normal load and these contacts are made of copper. The additional pair is the arcing contact and is made of carbon. When circuit breaker is being opened, the main contacts open first and during opening of main contacts the arcing contacts are still in touch with each other. As the current gets, a parallel low resistive path through the arcing contact during opening of main contacts, there will not be any arcing in the main contact. The arcing is only initiated when finally the arcing contacts are separated. The each of the arc contacts is fitted with an arc runner which helps, the arc discharge to move upward due to both thermal and electromagnetic effects as shown in the figure. As the arc is driven upward it enters in the arc chute, consisting of splitters. The arc in chute will become colder, lengthen and split hence arc voltage becomes much larger than system voltage at the time of operation of air circuit breaker, and therefore the arc is quenched finally during the current zero. Although this type of circuit breakers have become obsolete for medium voltage application, but they are still preferable choice for high current rating in low voltage application.

Air Blast Circuit Breaker These types of air circuit breaker were used for the system voltage of 245KV, 420KV and even more, especially where faster breaker operation was required. Air Blast Circuit Breaker has some specific advantages over oil circuit breaker which are listed as follows,

1) There is no chance of fire hazard caused by oil.

2) The breaking speed of circuit breaker is much higher during operation of air blast circuit breaker.

3) Arc quenching is much faster during operation of air blast circuit breaker.

4) The duration of arc is same for all values of small as well as high currents interruptions.

5) As the duration of arc is smaller, so lesser amount of heat realized from arc to current carrying contacts hence the service life of the contacts becomes longer.

6) The stability of the system can be well maintained as it depends on the speed of operation of circuit breaker.

7) Requires much less maintenance compared to oil circuit breaker.

There are also some disadvantages of air blast circuit breakers

1) In order to have frequent operations, it is necessary to have sufficiently high capacity air compressor.

2) Frequent maintenance of compressor, associated air pipes and automatic control equipments is also required.

3) Due to high speed current interruption there is always a chance of high rate of rise of re-striking voltage and current chopping.

4) There also a chance of air pressure leakage from air pipes junctions. As we said earlier that there are mainly two types of ACB, plain air circuit breaker and air blast circuit breaker. But the later can be sub divided further into three different categories. a)Axial Blast ACB. b) Axial Blast ACB with side moving contact. c) Cross Blast ACB.

Axial Blast Air Circuit Breaker :

In Axial Blast ACB the moving contact is in contact with fixed contact with the help of a spring pressure as shown in the figure. There is a nozzle orifice in the fixed contact which is blocked by tip of the moving contact at normal closed condition of the breaker. When fault occurs, the high pressure air is introduced into the arcing chamber. The air pressure will counter the spring pressure and deforms the spring hence the moving contact is withdrawn from the fixed contact and nozzle hole becomes open. At the same time the high pressure air starts flowing along the arc through the fixed contact nozzle orifice. This axial flow of air along the arc through the nozzle orifice will make the arc lengthen and colder hence arc voltage become much higher than system voltage that means system voltage is insufficient to sustain the arc consequently the arc is quenched.

Axial Blast ACB with side moving contact In this type of axial blast air circuit breaker the moving contact is fitted over a piston supported over a spring. In order to open the circuit breaker the air is admitted into the arcing chamber when pressure reaches to a predetermined value, it presses down the moving contact; an arc is drawn between the fixed and moving contacts. The air blast immediately transfers the arc to the arcing electrode and is consequently quenched by the axial flow of air.

Cross Blast Air Circuit Breaker:

The working principle of Cross Blast Air Circuit Breaker is quite simple. In this system of air blast circuit breaker the blast pipe is fixed in perpendicular to the movement of moving contact in the arcing chamber and on the opposite side of the arcing chamber one exhaust chamber is also fitted at the same alignment of blast pipe, so that the air comes from blast pipe can straightly enter into exhaust chamber through the contact gap of the breaker. The exhaust chamber is spit with arc splitters. When moving contact is withdrawn from fixed contact, an arc is established in between the contact, and at the same time high pressure air coming from blast pipe will pass through the contact gap and will forcefully take the arc into exhaust chamber where the arc is split with the help of arc splitters and ultimately arc is quenched.

For better Understanding click the following links: Link-1

2) The breaking speed of circuit breaker is much higher during operation of air blast circuit breaker.

3) Arc quenching is much faster during operation of air blast circuit breaker.

4) The duration of arc is same for all values of small as well as high currents interruptions.

5) As the duration of arc is smaller, so lesser amount of heat realized from arc to current carrying contacts hence the service life of the contacts becomes longer.

6) The stability of the system can be well maintained as it depends on the speed of operation of circuit breaker.

7) Requires much less maintenance compared to oil circuit breaker.

There are also some disadvantages of air blast circuit breakers

1) In order to have frequent operations, it is necessary to have sufficiently high capacity air compressor.

2) Frequent maintenance of compressor, associated air pipes and automatic control equipments is also required.

3) Due to high speed current interruption there is always a chance of high rate of rise of re-striking voltage and current chopping.

4) There also a chance of air pressure leakage from air pipes junctions. As we said earlier that there are mainly two types of ACB, plain air circuit breaker and air blast circuit breaker. But the later can be sub divided further into three different categories. a)Axial Blast ACB. b) Axial Blast ACB with side moving contact. c) Cross Blast ACB.

Axial Blast Air Circuit Breaker :

In Axial Blast ACB the moving contact is in contact with fixed contact with the help of a spring pressure as shown in the figure. There is a nozzle orifice in the fixed contact which is blocked by tip of the moving contact at normal closed condition of the breaker. When fault occurs, the high pressure air is introduced into the arcing chamber. The air pressure will counter the spring pressure and deforms the spring hence the moving contact is withdrawn from the fixed contact and nozzle hole becomes open. At the same time the high pressure air starts flowing along the arc through the fixed contact nozzle orifice. This axial flow of air along the arc through the nozzle orifice will make the arc lengthen and colder hence arc voltage become much higher than system voltage that means system voltage is insufficient to sustain the arc consequently the arc is quenched.

Axial Blast ACB with side moving contact In this type of axial blast air circuit breaker the moving contact is fitted over a piston supported over a spring. In order to open the circuit breaker the air is admitted into the arcing chamber when pressure reaches to a predetermined value, it presses down the moving contact; an arc is drawn between the fixed and moving contacts. The air blast immediately transfers the arc to the arcing electrode and is consequently quenched by the axial flow of air.

Cross Blast Air Circuit Breaker:

The working principle of Cross Blast Air Circuit Breaker is quite simple. In this system of air blast circuit breaker the blast pipe is fixed in perpendicular to the movement of moving contact in the arcing chamber and on the opposite side of the arcing chamber one exhaust chamber is also fitted at the same alignment of blast pipe, so that the air comes from blast pipe can straightly enter into exhaust chamber through the contact gap of the breaker. The exhaust chamber is spit with arc splitters. When moving contact is withdrawn from fixed contact, an arc is established in between the contact, and at the same time high pressure air coming from blast pipe will pass through the contact gap and will forcefully take the arc into exhaust chamber where the arc is split with the help of arc splitters and ultimately arc is quenched.

For better Understanding click the following links: Link-1

The motor or an electrical motor is a device that has brought about one of the biggest advancements in the fields of engineering and technology ever since the invention of electricity. A motor is nothing but an electro-mechanical device that converts electrical energy to mechanical energy. Its because of motors, life is what it is today in the 21st century. Without motor we had still been living in Sir Thomas Edison’s Era where the only purpose of electricity would have been to glow bulbs. There are different types of motor have been developed for different specific purposes. In simple words we can say a device that produces rotational force is a motor. The very basic principal of functioning of an electrical motor lies on the fact that force is experienced in the direction perpendicular to magnetic field and the current, when field and electric current are made to interact with each other. Ever since the invention of motors, a lot of advancements has taken place in this field of engineering and it has become a subject of extreme importance for modern engineers. This particular webpage takes into consideration, the above mentioned fact and provides a detailed description on all major electrical motors and motoring parts being used in the present era. Motor Starting and Running Currents and Rating Guide: A word of caution: The following article is based on National Electrical Manufacturers' Association (NEMA) tables, standards and nomenclature. This is somewhat different from Indian and European practice. The class designations are applicable only to NEMA compatible motors which are in use in the US only. However, the logic and pattern of calculations are the same everywhere. Hence the reader is cautioned to follow only the logical sequence of the calculations. Motor Starting Current: When typical induction motors become energized, a much larger amount of current than normal operating current rushes into the motor to set up the magnetic field surrounding the motor and to overcome the lack of angular momentum of the motor and its load. As the motor increases to slip speed, the current drawn subsides to match (1) the current required at the supplied voltage to supply the load and (2) losses to windage and friction in the motor and in the load and transmission system. A motor operating at slip speed and supplying nameplate horsepower as the load should draw the current printed on the nameplate, and that current should satisfy the equation

Horsepower = (voltage X current X power factor X motor efficiency X v3) / 746

Typical induction motors exhibit a starting power factor of 10 to 20 percent and a full-load running power factor of 80 to 90 percent. Smaller typical induction motors exhibit an operating full-load efficiency of approximately 92 percent, whereas large typical induction motors exhibit an operating full-load efficiency of approximately 97.5 percent.

Typical induction motors exhibit a starting power factor of 10 to 20 percent and a full-load running power factor of 80 to 90 percent. Smaller typical induction motors exhibit an operating full-load efficiency of approximately 92 percent, whereas large typical induction motors exhibit an operating full-load efficiency of approximately 97.5 percent.

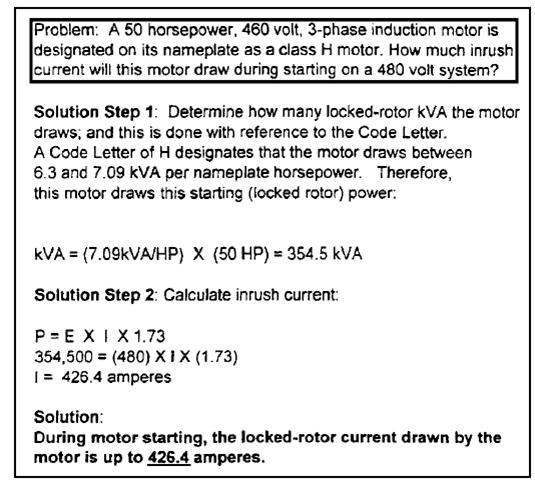

Since many types of induction motors are made, the inrush current from an individual motor is important in designing the electrical power supply system for that motor. For this purpose, the nameplate on every motor contains a code letter indicating the kilovoltampere/horsepower starting load rating of the motor. A table of these code letters and their meanings in approximate kVA and horsepower is shown in the following table.

Using these values, the inrush current for a specific motor can be calculated as

Because of the items listed above, motors that produce constant kVA loads make demands on the electrical power system that are extraordinary compared with the demands of constant kilowatt loads. To start them, the over current protection system must permit the starting current, also called the locked-rotor current, to flow during the normal starting period, and then the motor-running over current must be limited to approximately the nameplate full-load ampere rating. If the duration of the locked-rotor current is too long, the motor will overheat due to I2R heat buildup, and if the long-time ampere draw of the motor is too high, the motor also will overheat due to I2R heating. The National Electrical Code provides limitations on both inrush current and running current, as well as providing a methodology to determine motor disconnect switch ampere and horsepower ratings.

Motor Running Current:

Calculating Motor Branch-Circuit Overcurrent Protection and Wire Size

A 40 HP, 460 V, 3 phase, Code letter G, Service factor of 1.0 is planned for operation from a 460 V, 3 phase system. The name plate ampere is 50A. The motor is rated for continuous duty and the load is continuous. Solve for minimum sizes of branch circuit elements?

NEC Torque classes and characteristics

Classification or Types of Motor The primary classification of motor or types of motor can be tabulated as shown below,

History of Motor In the year 1821 British scientist Michael Faraday explained the conversion of electrical energy into mechanical energy by placing a current carrying conductor in a magnetic field which resulted in the rotation of the conductor due to torque produced by the mutual action of electrical current and field. Based on his principal the most primitive of machines a D.C.(direct current) machine was designed by another British scientist William Sturgeon in the year 1832. But his model was overly expensive and wasn’t used for any practical purpose. Later in the year 1886 the first electrical motor was invented by scientist Frank Julian Sprague. That was capable of rotating at a constant speed under a varied range of load, and thus derived motoring action.

INDEX

1) DC Motor

2) Synchronous Motor

3) 3 Phase Induction Motor

4) 1 Phase Induction Motor

5) Special Types of Motor Among the four basic classification of motors mentioned above the DC motor as the name suggests, is the only one that is driven by direct current. It’s the most primitive version of the electric motor where rotating torque is produced due to flow of electric current through the conductor inside a magnetic field. Rest all are A.C. electrical motors, and are driven by alternating current, for e.g. the synchronous motor, which always runs at synchronous speed. Here the rotor is an Electromagnet which is magnetically locked with stator rotating magnetic field and rotates with it. The speed of these machines are varied by varying the frequency (f) and number of poles (P), as Ns = 120 f/P. In another type of AC motor where rotating magnetic field cuts the rotor conductors, hence circulating current induced in these short circuited rotor conductors. Due to interaction of the magnetic field and these circulating currents the rotor starts rotates and continues its rotation. This is induction motor which is also known as asynchronous motor runs at a speed lesser than synchronous speed, and the rotating torque, and speed is governed by varying the slip which gives the difference between synchronous speed Ns , and rotor speed speed Nr, It runs governing the principal of EMF induction due to varying flux density, hence the name induction machine comes. Single phase induction motor like a 3 phase, runs by the principal of emf induction due to flux, but the only difference is, it runs on single phase supply and its starting methods are governed by two well established theories, namely the Double Revolving field theory and the Cross field theory. Apart from the four basic types of motor mentioned above, there are several types Of special electrical motors like Linear Induction motor(LIM),Stepper motor, Servo motor etc with special features that has been developed according to the needs of the industry or for a particular particular gadget like the use of hysteresis motor in hand watches because of its compactness.

For better Understanding click the following links:

Code Letter on motor name plate

|

kVA per HP with locked rotor

|

||

Minimum

|

Mean

|

Maximum

|

|

A

|

0

|

1.57

|

3.14

|

B

|

3.15

|

3.345

|

3.54

|

C

|

3.55

|

3.77

|

3.99

|

D

|

4

|

4.245

|

4.9

|

E

|

4.5

|

4.745

|

4.99

|

F

|

5

|

5.295

|

5.59

|

G

|

5.6

|

5.945

|

6.29

|

H

|

6.3

|

6.695

|

7.09

|

J

|

7.1

|

7.545

|

7.99

|

K

|

8

|

8.495

|

8.9

|

L

|

9

|

9.495

|

9.9

|

M

|

10

|

10.595

|

11.19

|

N

|

11.2

|

11.845

|

12.49

|

P

|

12.5

|

13.245

|

13.99

|

R

|

14

|

14.995

|

15.99

|

S

|

16

|

16.995

|

17.99

|

T

|

18

|

18.995

|

19.99

|

U

|

20

|

29.2

|

22.39

|

V

|

22.4

|

No Limit

|

No Limit

|

Using these values, the inrush current for a specific motor can be calculated as

Iinrush=(code letter value X horse power x 1000) /( v3 X Voltage)

An example of this calculation for a 50-hp code letter G motor operating at 460 V is shown below

Because of the items listed above, motors that produce constant kVA loads make demands on the electrical power system that are extraordinary compared with the demands of constant kilowatt loads. To start them, the over current protection system must permit the starting current, also called the locked-rotor current, to flow during the normal starting period, and then the motor-running over current must be limited to approximately the nameplate full-load ampere rating. If the duration of the locked-rotor current is too long, the motor will overheat due to I2R heat buildup, and if the long-time ampere draw of the motor is too high, the motor also will overheat due to I2R heating. The National Electrical Code provides limitations on both inrush current and running current, as well as providing a methodology to determine motor disconnect switch ampere and horsepower ratings.

Table 430-152 of the National Electrical Code provides the maximum setting of over current devices upstream of the motor branch circuit, and portions of this table are replicated below:

% of Full load current

|

||||

Motor type

|

Single element fuse

|

Dual-element time delay fuse

|

Inverse time breaker

|

Instantaneous & Magnetic trip breaker

|

Single phase motor

|

300

|

175

|

250

|

800

|

Three phase squirrel cage motor

|

300

|

175

|

250

|

800

|

Design E three phase squirrel cage

|

300

|

175

|

250

|

1100

|

Synchronous

|

300

|

175

|

250

|

800

|

Wound rotor

|

150

|

150

|

150

|

800

|

Direct current

|

150

|

150

|

150

|

250

|

For example, a 50 hp, Design B, 460V 3 phase motor has a full load current of 65A at 460V. The maximum rating of an inverse time breaker protecting the motor branch circuit would be 65A x 250%, or 162.5A. The next higher standard rating is 175A (US), so 175A is the maximum rating that can be used to protect the motor circuit.

|

||||

Motor Running Current:

The following figures illustrate the calculations required by specific types of motors in the design of electric circuits to permit these loads to start and to continue to protect them during operation.

Table of full-load currents for three-phase ac induction motors (A part of table 430-150 of NEC).

HP

|

208 V

|

230 V

|

460 V

|

575 V

|

0.5

|

2.5

|

2.2

|

1.1

|

0.9

|

0.75

|

3.5

|

3.2

|

1.6

|

1.3

|

1

|

4.6

|

4.2

|

2.1

|

1.7

|

1.5

|

6.6

|

6

|

3

|

2.4

|

2

|

7.5

|

6.8

|

3.4

|

2.7

|

3

|

10.6

|

9.6

|

4.8

|

3.9

|

5

|

16.7

|

15.2

|

7.6

|

6.1

|

10

|

30.8

|

28

|

14

|

11

|

15

|

46.2

|

42

|

21

|

17

|

20

|

59.4

|

54

|

27

|

22

|

25

|

74.8

|

68

|

34

|

27

|

30

|

88

|

80

|

40

|

32

|

40

|

114

|

104

|

52

|

41

|

50

|

143

|

130

|

65

|

52

|

60

|

169

|

154

|

77

|

62

|

75

|

211

|

192

|

96

|

77

|

100

|

273

|

248

|

124

|

99

|

125

|

343

|

312

|

156

|

125

|

150

|

396

|

360

|

180

|

144

|

200

|

528

|

480

|

240

|

192

|

Calculating Motor Branch-Circuit Overcurrent Protection and Wire Size

Article 430-52 of the National Electrical Code specifies that the minimum motor branch-circuit size must be rated at 125 percent of the motor full-load current found in Table 430-150 for motors that operate continuously, and Section 430-32 requires that the long-time overload trip rating not be greater than 115 percent of the motor nameplate current unless the motor is marked otherwise. Note that the values of branch-circuit over current trip (the long-time portion of a thermal-magnetic trip circuit breaker and the fuse melt-out curve ampacity) are changed by Table 430-22b for motors that do not operate continuously.

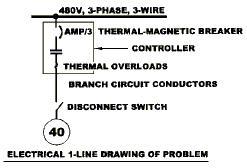

This is illustrated with a sample problem. Consider the circuit shown.

A 40 HP, 460 V, 3 phase, Code letter G, Service factor of 1.0 is planned for operation from a 460 V, 3 phase system. The name plate ampere is 50A. The motor is rated for continuous duty and the load is continuous. Solve for minimum sizes of branch circuit elements?

1. Take motor full load current from table 430-150 as 52A which is higher than name plate value.

2. Determine wire size: 125% of 52A = 65A.

3. Determine inverse time breaker setting: 250% of 52A = 130A, next standard rating is 150A.

4. Determine the rating of thermal overloads: 115% of 50A (name plate current) = 57.5 A

5. Determine disconnect switch ampere rating: 115% of 52A = 59.8 A

6. Determine controller HP rating: 40 HP (same as motor nameplate HP)

The completed circuit will look like this.

NEC Torque classes and characteristics

Design Letter

|

Starting current (%FLC)

|

Relative Efficiency

|

Slip in % rpm

|

Starting torque (%FLT)

|

Stalling torque (%FLT)

|

A

|

Depends upon-name plate-code letter Normally 630-1000%

|

High

|

3%

|

120-250%

|

200-275%

|

B

|

Normally 600-700%

|

High

|

1.5-3%

|

120-250%

|

200-275%

|

C

|

Normally 600-700%

|

High

|

1.5-3%

|

200-250%

|

190-225%

|

D

|

Normally 600-700%

|

Medium

|

5-8%

|

275%

|

275%

|

Classification or Types of Motor The primary classification of motor or types of motor can be tabulated as shown below,

INDEX

1) DC Motor

2) Synchronous Motor

3) 3 Phase Induction Motor

4) 1 Phase Induction Motor

5) Special Types of Motor Among the four basic classification of motors mentioned above the DC motor as the name suggests, is the only one that is driven by direct current. It’s the most primitive version of the electric motor where rotating torque is produced due to flow of electric current through the conductor inside a magnetic field. Rest all are A.C. electrical motors, and are driven by alternating current, for e.g. the synchronous motor, which always runs at synchronous speed. Here the rotor is an Electromagnet which is magnetically locked with stator rotating magnetic field and rotates with it. The speed of these machines are varied by varying the frequency (f) and number of poles (P), as Ns = 120 f/P. In another type of AC motor where rotating magnetic field cuts the rotor conductors, hence circulating current induced in these short circuited rotor conductors. Due to interaction of the magnetic field and these circulating currents the rotor starts rotates and continues its rotation. This is induction motor which is also known as asynchronous motor runs at a speed lesser than synchronous speed, and the rotating torque, and speed is governed by varying the slip which gives the difference between synchronous speed Ns , and rotor speed speed Nr, It runs governing the principal of EMF induction due to varying flux density, hence the name induction machine comes. Single phase induction motor like a 3 phase, runs by the principal of emf induction due to flux, but the only difference is, it runs on single phase supply and its starting methods are governed by two well established theories, namely the Double Revolving field theory and the Cross field theory. Apart from the four basic types of motor mentioned above, there are several types Of special electrical motors like Linear Induction motor(LIM),Stepper motor, Servo motor etc with special features that has been developed according to the needs of the industry or for a particular particular gadget like the use of hysteresis motor in hand watches because of its compactness.

Electrical Motor,

Working of ElectricMotor,

DC Motor,

Working Principle of DCMotor

Construction of DCMotor

Torque Equation of DC Motor

Types of DC Motor

Shunt Wound DC Motor

Series Wound DC Motor

Compound Wound DC Motor

Starting Methods of DCMotor

Three Point Starter

Four Point Starter

Speed Regulation of DC Motor

Speed Control of DCMotor

Three Phase InductionMotor

Linear Induction Motor

Synchronous Motor

Synchronous MotorExcitation

Hunting in SynchronousMotor

Motor Generator Set

Designing of control circuits using Contactors, Relays, Timers etc:

DOL, Star Delta Starter designing for 3 phase motors with specification:

DOL Starter:

Different starting methods are employed for starting induction motors because Induction Motor draws more starting current during starting. To prevent damage to the windings due to the high starting current flow, we employ different types of starters.

The simplest form of motor starter for the induction motor is the Direct On Line starter. The Direct On Line Motor Starter (DOL) consist a MCCB or Circuit Breaker, Contactor and an overload relay for protection. Electromagnetic contactor which can be opened by the thermal overloa relay under fault conditions.

Typically, the contactor will be controlled by separate start and stop buttons, and an auxiliary contact on the contactor is used, across the start button, as a hold in contact. I.e. the contactor is electrically latche closed while the motor is operating. Principle of Direct On Line Starter (DOL):

To start, the contactor is closed, applying full line voltage to the motor windings. The motor will draw a very high inrush current for a very short time, the magnetic field in the iron, and then the current will be limited to the Locked Rotor Current of the motor. The motor will develop Locked Rotor Torque and begin to accelerate towards full speed.

As the motor accelerates, the current will begin to drop, but will not drop significantly until the motor is at a high speed, typically about 85% of synchronous speed. The actual starting current curve is a function of the motor design, and the terminal voltage, and is totally independent of the motor load.

The motor load will affect the time taken for the motor to accelerate to full speed and therefore the duration of the high starting current, but not the magnitude of the starting current.

Provided the torque developed by the motor exceeds the load torque at all speeds during the start cycle, the motor will reach full speed. If the torque delivered by the motor is less than the torque of the load at any speed during the start cycle, the motor will stops accelerating. If the starting torque with a DOL starter is insufficient for the load, the motor must be replaced with a motor which can develop a higher starting torque.

The acceleration torque is the torque developed by the motor minus the load torque, and will change as the motor accelerates due to the motor speed torque curve and the load speed torque curve. The start time is dependent on the acceleration torque and the load inertia.

Note: DOL starting have a maximum start current and maximum start torque. This may cause an electrical problem with the supply, or it may cause a mechanical problem with the driven load. So this will be inconvenient for the users of the supply line, always experience a voltage drop when starting a motor. But if this motor is not a high power one it does not affect much.

Parts of DOL Starters:

Contactors & Coil:

DOL part -Contactor:

Magnetic contactors are electromagnetically operated switches that provide a safe and convenient means for connecting and interrupting branch circuits.

Magnetic motor controllers use electromagnetic energy for closing switches. The electromagnet consists of a coil of wire placed on an iron core. When a current flow through the coil, the iron of the magnet becomes magnetized, attracting an iron bar called the armature. An interruption of the current flow through the coil of wire causes the armature to drop out due to the presence of an air gap in the magnetic circuit.

Line-voltage magnetic motor starters are electro-mechanical devices that provide a safe, convenient, and economical means of starting and stopping motors, and have the advantage of being controlled remotely. The great bulk of motor controllers sold are of this type.

Contactors are mainly used to control machinery which uses electric motors. It consists of a coil which connects to a voltage source. Very often for Single phase Motors, 230V coils are used and for three phase motors, 415V coils are used. The contactor has three main NO contacts and lesser power rated contacts named as Auxiliary Contacts [NO and NC] used for the control circuit. A contact is conducting metal parts which completes or interrupt an electrical circuit.

NO-normally open

NC-normally closed

Over Load Relay (Overload protection)

Overload protection for an electric motor is necessary to prevent burnout and to ensure maximum operating life.

Under any condition of overload, a motor draws excessive current that causes overheating. Since motor winding insulation deteriorates due to overheating, there are established limits on motor operating temperatures to protect a motor from overheating. Overload relays are employed on a motor control to limit the amount of current drawn.

The overload relay does not provide short circuit protection. This is the function of over current protective equipment like fuses and circuit breakers, generally located in the disconnecting switch enclosure.

The ideal and easiest way for overload protection for a motor is an element with current-sensing properties very similar to the heating curve of the motor which would act to open the motor circuit when full-load current is exceeded. The operation of the protective device should be such that the motor is allowed to carry harmless over-loads but is quickly removed from the line when an overload has persisted too long.

DOL part - Termal Overload Relay:

Normally fuses are not designed to provide overload protection. Fuse is protecting against short circuits (over current protection). Motors draw a high inrush current when starting and conventional fuses have no way of distinguishing between this temporary and harmless inrush current and a damaging overload. Selection of Fuse is depend on motor full-load current, would “blow” every time the motor is started. On the other hand, if a fuse were chosen large enough to pass the starting or inrush current, it would not protect the motor against small, harmful overloads that might occur later.

The overload relay is the heart of motor protection. It has inverse-trip-time characteristics, permitting it to hold in during the accelerating period (when inrush current is drawn), yet providing protection on small overloads above the full-load current when the motor is running. Overload relays are renewable and can withstand repeated trip and reset cycles without need of replacement. Overload relays cannot, however, take the place of over current protection equipment.

The overload relay consists of a current-sensing unit connected in the line to the motor, plus a mechanism, actuated by the sensing unit, which serves, directly or indirectly, to break the circuit.

Overload relays can be classified as being thermal, magnetic, or electronic

Thermal Relay: As the name implies, thermal overload relays rely on the rising temperatures caused by the overload current to trip the overload mechanism. Thermal overload relays can be further subdivided into two types: melting alloy and bimetallic.

Magnetic Relay: Magnetic overload relays react only to current excesses and are not affected by temperature.

Electronic Relay: Electronic or solid-state overload relays, provide the combination of high-speed trip, adjustability, and ease of installation. They can be ideal in many precise applications.

Wiring of DOL Starter:

1. Main Contact

Contactor is connecting among Supply Voltage, Relay Coil and Thermal Overload Relay.

L1 of Contactor Connect (NO) to R Phase through MCCB

L2 of Contactor Connect (NO) to Y Phase through MCCB

L3 of Contactor Connect (NO) to B Phase through MCCB.

NO Contact (-||-):

(13-14 or 53-54) is a normally Open NO contact (closes when the relay energizes)

Contactor Point 53 is connecting to Start Button Point (94) and 54 Point of Contactor is connected to Common wire of Start/Stop Button.

NC Contact (-|/|-): (95-96) is a normally closed NC contact (opens when the thermal overloads trip if associated with the overload block)

2. Relay Coil Connection

A1 of Relay Coil is connecting to any one Supply Phase and

A2 is connecting to Thermal over Load Relay’s NC Connection (95).

3. Thermal Overload Relay Connection:

T1,T2,T3 are connect to Thermal Overload Relay

Overload Relay is Connecting between Main Contactor and Motor

NC Connection (95-96) of Thermal Overload Relay is connecting to Stop Button and Common Connection of Start/Stop Button.

Wiring Diagram of DOL Starter:

Direct On Line Starter - Wiring Diagram

Working principle of DOL Starter

The main heart of DOL starter is Relay Coil. Normally it gets one phase constant from incoming supply Voltage (A1).when Coil get second Phase relay coil energizes and Magnet of Contactor produce electromagnetic field and due to this Plunger of Contactor will move and Main Contactor of starter will closed and Auxiliary will change its position NO become NC and NC become (shown Red Line in Diagram) .

Pushing Start Button:

When We Push the start Button Relay Coil will get second phase from Supply Phase-Main contactor(5)-Auxiliary Contact(53)-Start button-Stop button-96-95-To Relay Coil (A2).Now Coil energizes and Magnetic field produce by Magnet and Plunger of Contactor move. Main Contactor closes and Motor gets supply at the same time Auxiliary contact become (53-54) from NO to NC .

Release Start Button:

Relay coil gets supply even though we release Start button. When We release Start Push Button Relay Coil gets Supply phase from Main contactor (5)-Auxiliary contactor (53) – Auxiliary contactor (54)-Stop Button-96-95-Relay coil (shown Red / Blue Lines in Diagram).

In Overload Condition of Motor will be stopped by intermission of Control circuit at Point 96-95.

Pushing Stop Button:

When we push Stop Button Control circuit of Starter will be break at stop button and Supply of Relay coil is broken, Plunger moves and close contact of Main Contactor becomes Open, Supply of Motor is disconnected.

DOL - Wiring scheme

Motor Starting Characteristics on DOL Starter

Available starting current: 100%.

Peak starting current: 6 to 8 Full Load Current.

Peak starting torque: 100%

Advantages of DOL Starter:

Most Economical and Cheapest Starter

Simple to establish operate and maintain

Simple Control Circuitry

Easy to understand and trouble-shoot.

It provides 100% torque at the time of starting.

Only one set of cable is required from starter to motor.

Motor is connected in delta at motor terminals.

Disadvantages of DOL Starter:

It does not reduce the starting current of the motor.

High Starting Current: Very High Starting Current (Typically 6 to 8 times the FLC of the motor).

Mechanically Harsh: Thermal Stress on the motor, thereby reducing its life.

Voltage Dip: There is a big voltage dip in the electrical installation because of high in-rush current affecting other customers connected to the same lines and therefore not suitable for higher size squirrel cage motors

High starting Torque: Unnecessary high starting torque, even when not required by the load, thereby increased mechanical stress on the mechanical systems such as rotor shaft, bearings, gearbox, coupling, chain drive, connected equipments, etc. leading to premature failure and plant downtimes.

Features of DOL starting:

For low- and medium-power three-phase motors

Three connection lines (circuit layout: star or delta)

High starting torque

Very high mechanical load

High current peaks

Voltage dips

Simple switching devices

Direct On Line Motor Starter (DOL) is suitable for:

A direct on line starter can be used if the high inrush current of the motor does not cause excessive voltage drop in the supply circuit. The maximum size of a motor allowed on a direct on line starter may be limited by the supply utility for this reason. For example, a utility may require rural customers to use reduced-voltage starters for motors larger than 10 kW.

DOL starting is sometimes used to start small water pumps, compressors, fans and conveyor belts.

Direct On Line Motor Starter (DOL) is NOT suitable for:

The peak starting current would result in a serious voltage drop on the supply system

The equipment being driven cannot tolerate the effects of very high peak torque loading

The safety or comfort of those using the equipment may be compromised by sudden starting as, for example, with escalators and lifts.

Star Delta Starter:

Star Delta Starter:

STAR DELTA connection Diagram and Working principle:

Descriptions: A Dual starter connects the motor terminals directly to the power supply. Hence, the motor is subjected to the full voltage of the power supply. Consequently, high starting current flows through the motor. This type of starting is suitable for small motors below 5 hp (3.75 kW) Reduced-voltage starters are employed with motors above 5

hp. Although Dual motor starters are available for motors less than 150kW on 400 V and for motors less than 1 MW on 6.6 kV. Supply reliability and reserve power generation dictates the use of reduced voltage or not to reduce the starting current of an induction motor the voltage across the motor need to be reduced. This can be done by 1. Autotransformer starter,

2. Star-delta starter or

3. Resistor starter.

2. Star-delta starter or

3. Resistor starter.

Now-a-days VVVF drive used extensively for speed control serves this purpose also.

In dual starter the motor is directly fed from the line and in star delta starter then motor is started initially from star and later during running from delta. This is a starting method that reduces the starting current and starting torque. The Motor must be delta connected during a normal run, in order to be able to use this starting method.

The received starting current is about 30 % of the starting current during direct on line start and the starting torque is reduced to about 25 % of the torque available at a D.O.L start.

More: Star/Delta starters are probably the most common reduced voltage starters in the 50Hz world. (Known as Wye/Delta starters in the 60Hz world). They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply.

Component: The Star/Delta starter is manufactured from three contactors, a timer and a thermal overload. The contactors are smaller than the single contactor used in a Direct on Line starter as they are controlling winding currents only. The currents through the winding are 1v3 = 0.58 (58%) of the current in the line. this connection amounts to approximately 30% of the delta values. The starting current is reduced to one third of the direct starting current.

How it works?

There are two contactors that are close during run, often referred to as the main contactor and the delta contactor. These are AC3 rated at 58% of the current rating of the motor. The third contactor is the star contactor and that only carries star current while the motor is connected in star. The current in star is one third of the current in delta, so this contactor can be AC3 rated at one third of the motor rating. In operation, the Main Contactor (KM3) and the Star Contactor (KM1) are closed initially, and then after a period of time, the star contactor is opened, and then the delta contactor (KM2) is closed. The control of the

contactors is by the timer (K1T) built into the starter. The Star and Delta are electrically interlocked and preferably mechanically interlocked a well.

In effect, there are four states:

OFF State: All Contactors are open

Star State: The Main and the Star contactors are closed and the delta contactor is open. The motor is connected in star and will produce one third of DOL torque at one third of DOL current.

Open State: The Main contactor is closed and the Delta and Star contactors are open. There is voltage on one end of the motor windings, but the other end is open so no current can flow. The motor has a spinning rotor and behaves like a generator.

Delta State: The Main and the Delta contactors are closed. The Star contactor is open. The motor is connected to full line voltage and full power and torque are available.

This type of operation is called open transition switching because there is an open state between the star

Practical wiring session on different controls: Make practice in your home.....

Motor drives- AC drives and DC drives:

Motor drives- AC drives and DC drives:

Classification of electrical drives:

The classification of electrical drives can be done depending upon the various components of the drive system. Now according to the design, the drives can be classified into three types such as single-motor drive, group motor drive and multi motor drive. The single motor types are the very basic type of drive which are mainly used in simple metal working, house hold appliances etc. Group electric drives are used in modern industries because of various complexities. Multi motor drives are used in heavy industries or where multiple motoring units are required such as railway transport. If we divide from another point of view, these drives are of two types:

i) Reversible types and

ii) Non reversible types.

This depends mainly on the capability of the drive system to alter the direction of the flux generated. So, several classification of drive is discussed above.

Parts of Electrical Drives

The diagram which shows the basic circuit design and components of a drive, also shows that, drives have some fixed parts such as, load, motor, Power modulator control unit and source. These equipments are termed as parts of drive system. . Now, loads can be of various types i.e they can have specific requirements and multiple conditions, which are discussed later, first of all we will discuss about the other four parts of electrical drives i.e motor, power modulators, sources and control units.

Electric motors are of various types. The dc motors can be divided in four types – shunt wound dc motor, series wound dc motor, compound wound dc motor and permanent magnet dc motor. And AC motors are of two types –induction motors and synchronous motors. Now synchronous motors are of two types – round field and permanent magnet. Induction motors are also of two types – squirrel cage and wound motor. Besides all of these, stepper motors and switched reluctance motors are also considered as the parts of drive system.

So, there are various types of electric motors, and they are used according to their specifications and uses. When the electrical drives were not so popular, induction and synchronous motors were usually implemented only where fixed or constant speed was the only requirement. And for variable speed drive applications, dc motors were used. But as we know that, induction motors of same rating as a dc motors have various advantages like they have lighter weight, lower cost, lower volume and there is less restriction on maximum voltage, speed and power ratings. For these reasons, the induction motors are rapidly replaced the dc motors. Moreover induction motors are mechanical stronger and requires less maintenance. When synchronous motors are considered, wound field and permanent magnet synchronous motors have higher full load efficiency and power factor than induction motors, but the size and cost of synchronous motors are higher than induction motors for the same rating.

Brush less dc motors are similar to permanent magnet synchronous motors. They are used for servo applications and now a day’s used as an efficient alternative to dc servo motors because they don’t have the disadvantages like commendation problem. Beside of these, stepper motors are used for position control and switched reluctance motors are used for speed control.

Power Modulators - are the devices which alter the nature or frequency as well as changes the intensity of power to control electrical drives. Roughly, power modulators can be classified into three types,

i) Converters,

ii) Variable impedance,

iii) Switching circuits.

As the name suggests, converters are used to convert currents from one type to other type. Depending on the type of function, converters can be divided into 5 types –

ii. ac Regulators

iii. Choppers or dc-dc converters

iv. Inverters

v. Cycloconverters AC to DC converters are used to obtain fixed dc supply from the ac supply of fixed voltage.

The very basic diagram of ac to dc converters is like.

AC Regulators are used to obtain the regulated ac voltage, mainly auto transformers or tap changer transformers are used in these regulators.

Choppers or dc-dc converters are used to get a variable DC voltage. Power transistors, IGBT’s, GPO’s, power MOSFET’s are mainly used for this purpose.

Cyclo-converters are used to convert the fixed frequency and fixed voltage ac into variable frequency and variable voltage ac. Thyristors are used in these converters to control the firing signals.

Variable Impedances are used to controlling speed by varying the resistance or impedance of the circuit. But these controlling methods are used in low cost dc and ac drives. There can be two or more steps which can be controlled manually or automatically with the help of contactors. To limit the starting current inductors are used in ac motors.

Switching circuits in motors and electrical drives are used for running the motor smoothly and they also protects the machine during faults. These circuits are used for changing the quadrant of operations during the running condition of a motor. And these circuits are implemented to operate the motor and drives according to predetermined sequence, to provide interlocking, to disconnect the motor from the main circuit during any abnormal condition or faults.

Sources may be of 1 phase and 3 phase. 50 Hz ac supply is the most common type of electricity supplied in India, both for domestic and commercial purpose. Synchronous motors which are fed 50 Hz supply have maximum speed up to 3000 rpm, and for getting higher speeds higher frequency supply is needed. Motors of low and medium powers are fed from 400V supply, and higher ratings like 3.3 kv, 6.6 kv, 11 kv etc are provided also.

Control unit – choice of control unit depends upon the type of power modulator that is used. These are of many types, like when semiconductor converters are used, then the control unit consists of firing circuits, which employ linear devices and microprocessors.

So, the above discussion provides us a simple concept about the several parts of electrical drive.

Advantages of Electrical drives

Electrical drives are readily used these days for controlling purpose but this is not the only the advantage of Electrical drives. There are several other advantages which are listed below –

1)These drives are available in wide range torque, speed and power.